Story:

CSR and Innovation- The Role of Corporate Culture for Sustainability Innovation at Henkel

In the 1970s synthetic textiles became fashionable, which made it necessary to lower washing temperatures and adapt the detergent ingredients to these temperatures. Enzymes were introduced as a major ingredient, because they were are effective at lower temperatures. As a result the energy use per washing has been cut by half since their introduction. Early on, Henkel communicated this environmental advantage within its advertising.

Another challenge was the necessity of substituting phosphates as ingredients of the detergents, because phosphates led to eutrophication -- often manifested as the excessive growth of algae due to the nutrient properties of phosphates entering the water. Since 1986 Persil has been free of phosphates. Finally, the volume of the detergent (transport) and the packaging (material and waste) are important aspects for potentially optimising detergent and home care products with respect to their environmental impact.

For Henkel sustainability has a strategic dimension. Therefore all business activities throughout the value chain focus on the challenges of sustainable development. Henkel has grouped these challenges according to five focal areas: energy and climate, water and wastewater, materials and waste, health and safety, and social progress.

With respect to sustainability, progress has been made in recent years, particularly when focusing on products as well as the production process. Since 1998 energy use has fallen by 40 % per tonne of product, water use by 40 % per tonne of product and waste generation by 37 % per tonne of product. Work-related accidents declined by 68 %. New objectives have been set up. By the year 2012 work-related accidents should be reduced by 20 % compared to the year 2007. Reduced energy use, water use and waste shall achieve further improvements between 10 % and 15 % compared with the year 2007.

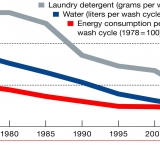

Henkel continuously improves the quality of its detergents. A board member once described the relationship between the quality of the brand and innovation as follows: “Persil remains Persil, because Persil does not remain Persil”. This means that during the past 30 years the performance of the washing powder has improved tremendously while during the same time the environmental impact has been reduced significantly. Due to the continuous improvement of the formulae for washing powder gels and tabs the amount of detergent, energy, and water needed per wash cycle has been reduced continuously. This development is the result of several innovation steps. The research and development department for detergents worked continuously on the improvement of these product qualities. In order to produce a successful product, market demand and the behaviour of competitors need to be considered. Henkel therefore established strong coordination between the marketing department and the product development unit.

Main Drivers and Obstacles for Sustainability Innovations

Today the issues of climate protection, prices for energy, and corporate responsibility attract more attention than they used to in the past. These issues have become more relevant for purchasing decisions. However prices/costs and product performance still remain decisive for the purchasing decisions of the customers. As long as energy prices remain high (which was the case when this study was being prepared) products which lower the energy costs for the customer will become more interesting. Inside Henkel corporate culture plays a major role. Quite early Henkel dealt actively with environmental problems. When, for example in the 1950s synthetic detergents and tensides were used and as a result rivers and lakes were crowned with mountains of foam Henkel reacted and started to systematically analyze the water in the Rhine and its tributaries in order to determine the levels of washing active substances. As a result, the company introduced regular ecological quality checks for all their laundry detergents and household cleaners. This, in combination with the influence of the culture of a family-led company paved the way for a corporate culture which places a huge emphasis on environmental and sustainability issues. The company regards its corporate culture as an important asset because at the end of the day neither the development of ideas nor their uptake can be influenced by a formal target setting system. In this respect, awareness and values are much more important. However a general barrier for innovative sustainable products is the mindset of the customer. Consumers and customers are accustomed to sticking to certain processes and product qualities. In the market for detergents, for example, the behaviour of the competitors can become a serious obstacle for sustainable product improvements. If a competitor offers detergents with a large volume some consumers buy these since they have the (wrong) impression they get more goods for the same price. Such behaviour of competitors prevents a reduction in size of the packaging.

The Design of Innovation Management at Henkel

The company’s innovation processes are organised according to the stage gate approach with clearly defined steps. The starting point of the process is the consideration of the needs and current difficulties of existing customers as well as within its own value generation processes. Innovation management uses roadmaps to consider future developments. Roadmapping involves taking a look at possible developments from two perspectives: from now into the future and from an expected future back to today. When setting up roadmaps Henkel considers eight different areas such as consumer markets, industry markets, or competitors (see Figure 4). Aspects such as climate change, scarcity of water, or rising prices for raw materials are considered in the category “external”. Demographic change and the rising importance of health awareness are part of the category “consumer”. When a team for a certain innovation project is established, it is a requirement that for each of these categories a suitably qualified team member is selected and assumes responsibility for this area.

The Role of the CSR Department in Innovation Management

At Henkel CSR has several roots. One is the mindset of the founders which entails a responsibility towards employees, consumers and the environment. The first self-working detergent, Persil, reduced the amount of effort necessary for consumers to do laundry. It also no longer contained chlorine, which reduced the environmental impact. Since the company is still owned by descendants of the Henkel family this tradition is still very much alive. The early confrontation with the environmental impact of the products the health risks in the production process led to an organisational structure in the company that considers these aspects. As time went on, these issues seem to become closely linked to each other. The early experiences led to the establishment of a corporate culture which is open to and serious about sustainability issues. Sustainability management fosters the awareness for the relevance of these issues through sustainability communication and the continuous integration of respective mechanisms in the existing management processes. The definition of the focus areas (energy and climate, water and waste, etc.) was an important step. The respective issues and tasks had been considered before, but a clear structure was missing. The clarity provided by the focal areas (see above) has several advantages. These focal areas created a mutual understanding which made communication easier and enabled a systematic integration of these issues in organisational processes. The early recognition of certain issues which are relevant for research, development and marketing is a further contribution of sustainability management to innovation management.

This case study is based on a telephone interview with Dr. Arnd Scheidgen, Head of Global R&D Chemistry Laundry & Home Care, Henkel in Summer 2008 and his presentation on September 2, 2008 in Berlin. Download the English language slides at http://www.4sustainability.org/seiten/csr-multistakeholder-CSR_und_Innov...

The case study was prepared within a research project funded by the German Environmental Ministry.

Casestudies on CSR and Innovation: Company Cases from Germany and the USA.

Download http://www.4sustainability.org/downloads/Loew_Clausen_etal-Case_Studies_on_CSR_and_Innovation.pdf

In this publication are further case studies from Bosch, Siemens, HP, DuPond, General Electric

Presentation of Dr. Arnd Scheidgen, Head of Global R&D Chemistry Laundry & Home Care, Henkel

Download of the English language slides at http://www.4sustainability.org/seiten/csr-multistakeholder-CSR_und_Innovation.htm

You need to register in order to submit a comment.