Story:

How Two Clean Tech Start-Ups - Pi Mobility and Hydrovolts - Used Technology to Enable Innovation and Unlock Long-Term Social and Environmental Benefits

Clean technology entrepreneurs are challenged to optimize their solutions for sustainability while getting to market quickly and profitably. Advancing their efficiency and effectiveness is key to supporting and resolving possible tension between these two goals. Design technology can be a critical enabler in this process and wholly revolutionize how teams approach product development, the speed and scope of their efforts and ultimately how they are delivering on their mission of creating a better world. Examples of two U.S. clean technology companies illustrate how the fundamentals of sustainable innovation can be applied in very different settings.

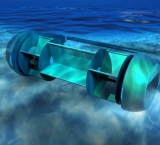

Hydrovolts is developing micro hydropower turbines. Hydrovolts used Autodesk technology as a way to fundamentally change the engineering culture at its company and shift it in a more environmentally minded direction.

Pi Mobility is a manufacturer of electric bicycles. Their key innovation was to use our technology as a way to create a bike that lasts for decades—and to move away from the short term, “throwaway” mentality and culture that permeate many electric bike companies.

These two ventures found an essential resource in the Autodesk Clean Tech Partner Program, which provides up to $150,000 worth of design software to clean tech companies for a nominal fee. Hydrovolts joined the Autodesk Clean Tech Program in 2009, and Pi Mobility joined in 2010 after hearing about it from colleagues in the clean tech community. The software lets them build digital prototypes of their ideas, to design, visualize, and simulate their products under real-world conditions.

Through the Autodesk Clean Tech Partner Program I am able to collaborate with clean tech innovators who are at the forefront of change, pushing the boundaries to find creative solutions to significant problems. Although small in size, these companies are giants in their fields and I truly am amazed by what they are accomplishing.

When Burt Hamner, founder and CEO of Hydrovolts, decided that he would focus his technology development on micro hydropower turbines that could run in irrigation canals and water aqueducts, he ran into several challenges. First, nobody had successfully done this before—there was no precedent.

Secondly, whatever type of product he developed would have to be an environmentally sound product, because the first thing people want to know before you drop something into their water system is whether or not it will contaminate their water. A “green” mindset was key—but how to best infuse that mindset into engineering efforts?

“I believe that most intelligent people feel some sense of environmental consciousness,” says Hamner. “But on a day-to-day basis, how is that put into practice? If you’re an engineer trained to do design and engineering in a specific field, you’re almost never also trained to think about all the environmental implications of what you’re doing. That’s what environmental engineering degrees are for, right? As a result, the vast majority of the design engineers out there have no understanding of the environmental impact of their designs. I wanted to change that in my company.”

Meanwhile, Marcus Hays, CEO of Pi Mobility, saw a different problem that needed tackling: the “throwaway” mentality in the electric bike industry.

“When I first encountered electric bicycles, most models were imported from a variety of countries, especially China,” said Hays. “The bikes typically relied on an injection molding manufacturing process, which produced parts made of a variety of thermoplastics. While initially pleasing in appearance, the plastic parts raised questions of reliability and tended toward unsightly discolorations and dangerous cracks. All too often, those bikes were simply tossed on the junk heap. As an advocate for electric bikes, I felt these problems had to be solved.”

Both these companies were faced with variations on the challenge inherent in sustainable innovation: how to create lasting value to achieve positive impact while taking into account the larger system and stakeholders therein. And as startups, they needed a way to do this with limited means and time.

For Hydrovolts, the way to start the transformation of its engineering efforts toward a more environmentally minded direction was through the introduction of Autodesk Inventor Eco Materials Adviser into its workflow.

Eco Materials Adviser is a tool within Autodesk ® Inventor ®, mechanical design and engineering software that lets engineers run real-time eco impact analyses on options for product materials and understand how different choices can affect its CO2 footprint, embedded energy, water usage, RoHS (Restriction on Hazardous Substances), food compliance and end-of-life behavior – traded off against cost.

Any engineer, green or otherwise, can use this capability to perform valuable analysis. No significant training is necessary because the engineer operates the tool from within their familiar 3D modeling environment.

“Being able to perform stress and force analysis on individual components enables us to drive down costs and more efficiently and accurately estimate lifecycles,” says Michael Layton, COO of Hydrovolts, “Being able to use the Eco Materials Adviser, we are also able to select more ecologically friendly materials and continue to reduce the carbon footprint of the products we take to market.”

Hamner adds, “I have long felt that too many organizations make the mistake of trying to make an engineer into an environmentalist. It’s a much better idea to make an engineer into a better engineer, by giving them good design tools—and then the environmental benefits will be a part of that.”

Pi Mobility’s way to change the “throwaway” mentality of the electric bike industry was to add residual value to a product that typically had not been vested with any residual value. They did this by building a bike that is designed and engineered to last for 30, 40, or even 50 years. It is not a “throwaway” bike.

“Rather than rely on brittle plastics for a multitude of parts, we used Autodesk Inventor design software to create an elegant, solitary arch of recycled aluminum for the Pi Cycle’s frame,” says Hays. “Not only does recycled aluminum last considerably longer than plastic, the batteries and electronic components reside safely within the aluminum tube rather than an injection-molded plastic battery enclosure, better protecting them from the elements and providing more efficient heat dissipation.”

Perhaps best of all, the single tube used in the PiCycle’s “battery agnostic design” means they can conceivably handle any battery or chemical process that produces electricity, allowing for easy upgrades in the future. “Changes to the design can be embedded very rapidly,” says Hays. The team was able to create a 3D digital prototype within three weeks of receiving the software that enabled them to see they could change the diameter of their tube at a significant savings.

All of this “future proofing” adds residual value to the PiCycle - a complete 180 from the “planned obsolescence” model that most bike companies follow.

Speaking further to the core cultural challenge of transforming engineering efforts to be more environmentally minded, Hamner says: “Imagine you’ve got an engineer or designer sitting at their desk working on their day-to-day tasks. Do you think you can go up to them and suddenly change their ethics or values? Help them become somebody who cares more about the world? Well, you can try. But it’s sort of like the old saying tells us: ‘Don’t try to teach a pig to sing. It wastes your time and annoys the pig’.”

What Hamner realized is that like many people, engineers are interested in making better environmental choices. They just don’t know how—and they’re not going to do it if it takes them a lot of extra work.

The fix was to present software like Inventor Eco Materials Adviser as first and foremost making them smarter and better at their job; and secondarily as making them “greener.”

“The order of presentation is key,” said Hamner. “If you do it the other way around, it does not work. Engineers want results – they want to become smarter and better at their jobs. They don’t want to be told to think green and then they’ll become smarter and better at their jobs. They want to become smarter and better at their jobs, and then become greener.”

In this manner, Hamner was able to make Hydrovolts into a more profoundly principled and socially accountable organization: one that could make a product that not only makes the world a better place by generating clean energy, but was itself developed in a clean and environmentally friendly manner.

Pi Mobility had its own challenges to overcome in an impatient industry that had historically been focused on pumping out cheap products to try and turn a profit.

“Most of our competitors have gone out of business over the past 15 years,” says Hays. “They go bankrupt because their investors look at some market research and decide that, for example, $2,000 is the “magic price point” for an electric bike—and that in order to be a profitable business, the bike company needs to sell a million units. You then have a bike company trying to squeeze $6,000 worth of costs into a $2,000 bike. Long before the bike company has sold a million units—or even reached the break-even point--they’ve gone out of business.”

How was Pi Mobility able to sidestep this fate? By focusing on becoming profitable early.

The company decided that they were going to sell the bike at an amount of money that would allow them to be profitable, rather than at some arbitrary “magic” price point. Accordingly, they offer $6,000 and $9,000 bikes because they believe there’s an early adopter community who will pay a premium to own a unique, well designed and well engineered bike.

This focus, and the resulting design, has enabled Pi Mobility to be a fundamentally more patient organization. They are profitable within the sales that they have, and that gives them the breathing room to make the kinds of products they want to make rather than cheap commodities.

The introduction of environmental impact software into the engineering workflow has benefitted Hydrovolts in several important ways. For starters, they are able to examine the environmental profiles of different materials—say, fiberglass vs. aluminum—before they use them to construct a turbine, and construct an environmental footprint for each design option.

Not only does this help Hydrovolts make better products and material tradeoffs, it is also extremely important in showing its customers that its turbines are environmentally safe.

“In a world where customers are starting to be more aware of the environmental differences between products, the competitor who can demonstrate competence in environmental performance knowledge stands out and is more likely to get business,” said Hamner.

Pi Mobility’s switch to a long-term mentality—by designing a sturdy bike that is meant to last 30, 40, or even 50 years and thus can command a premium price—has a string of associated benefits.

For starters, thanks to the less labor-intensive design of the PiCycle’s single tube, Pi Mobility has been able to maintain production in the United States and still be profitable.

“We are one of the only manufacturers in our market to create our product locally and onshore,” said Hays. “The bike is designed, engineered, cut, welded, assembled and painted all in the U.S.”

He added, “We can create smaller volumes wherever there are enough Pi riders and be profitable. For a small company like ours, that means much better quality control and throughput. And, of course, by producing our bikes locally, much of the transportation carbon that often affects even environmentally sustainable goods can be eliminated.”

As the examples of Hydrovolts and Pi Mobility demonstrate, technology can be an enabler for companies to change the culture of their companies toward a more long-term and sustainable viewpoint.

Key lessons for replication:

Applying digital prototyping technology can unlock business opportunities and enable new initiatives and team efforts that may not otherwise have been economically viable. Using best-in-class design tools can accelerate this process.

- Engineers want to be engineers

If you’re going to introduce environmental impact analysis software to your engineers (and if you haven’t already, you will) position it first and foremost as giving them data that helps them perform better at their jobs. Do not tell them that you’re going to make them “green” – just give them tools that make them better at their jobs.

For engineering centric business, it is key to start cultural change at that center of core competency. If you can innovate the engineering process, the cultural shift dominoes from there and becomes the norm.

- Stakeholders matter

Look beyond the “four walls” of your product to the larger context of where the materials used in creating it are coming from, how it will be used and for how long, and how and when it should finish its useful life. Then map this to the stakeholders along the way at each phase and consider whose needs should be considered and whether an engagement strategy is needed. Taking stakeholders into account early in the design process can help avoid costly delays in enlisting their support downstream, since you will have already handled their objections, concerns, or aspirations.

- Cheaper isn’t always better

For companies looking to shift society away from a “throwaway” culture, the answer is not to develop cheaper and cheaper products in a perpetual “race to the bottom.” Instead, use technology to raise the bar within your product category and create something innovative and enduring—and then take an honest assessment of how much money you need to charge for that product in order to be profitable. Because if a company isn’t profitable, it isn’t going to be able to affect any shifts toward a more principled and patient capitalism—because it won’t be around to do so.

Burt Hamner, CEO, Hydrovolts

Marcus Hays, CEO, Pi Mobility

Autodesk and Inventor are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names, or trademarks belong to their respective holders. Autodesk reserves the right to alter product and services offerings, and specifications and pricing at any time without notice, and is not responsible for typographical or graphical errors that may appear in this document. © 2012 Autodesk, Inc. All rights reserved.

Image below: Hydrovolts hydropower turbine. Image courtesy of Hydrovolts.

Image below: the PiCycle. Image courtesy of Pi Mobility.

You need to register in order to submit a comment.