Story:

How to start a movement in your company - Part 1 - overcoming cynicism, skepticism, and resistance

This is the story of how a team of highly engaged employees executed a large business transformation from the bottoms-up. By reaching across functional, geographic and organizational boundaries, focusing on a common vision, and locking arms together, they overcame years of stagnation and cynicism and demonstrated a real cultural change in less than one year.

After 4 years of false starts and over $XXM spent on consultants, software, and FTE's, every "transformational" initiative we tried failed. Cynicism grew rampant about the "flavor of the month" initiative. Employees felt that management was totally disconnected from reality. However, the consultants weren't wrong. The underlying operating system was falling apart. Without massive change the system would crash, meaning, we would be unable to profitably serve our customers and compete in the 21st Century. Something had to change.

Like many of these stories, timing and serendipity often come into play. One of our sales VP's was furious. We'll call him John. Last October John got up at the global sales meeting and railed against the operations group. "We would have sold 'X-millions' if only operations could deliver." Heads nodded in agreement. Whenever sales had a bad year operations was the first whipping-boy. But simply presenting a diatribe wasn't enough. John was on a righteous mission to turn over the tables and whip operations into shape.

A week later he showed up at Bill's (VP of operations) office, closed the door behind him and proceeded to give him the corporate equivalent of a shakedown. Now John is a 6' 4" burly Irishman, whom I saw drink 12 pints of Guiness in one sitting. He towered over Bill and proceeded to give him every instance of ops' failures. Bill sat patiently like a zen-master, sitting on his pilates ball (he used this instead of a chair), chewing on an apple. When John paused he calmly asked, "are you finished?" Well, that triggered another 10 minute rant. When John finally finished, Bill said, "you're right. Delivery is poor, and I'm willing to help."

Bill's non-defensiveness was like a master judo move. It totally disarmed John. "However," Bill said, "I can't solve delivery on 80,000 SKU's."

We were a $1B company, yet we sold more SKU's than Target, a $60B giant. The SKU proliferation created a literal gridlock in our supply-chain. Since we were operating under a build-to-forecast model, no matter how brilliant our SAP-guru master schedulers were, we invariably guessed product mix wrong. When the real orders came in, we were fighting fires just to ship even products that were high-runners. Our operations literally looked like the I-405 in Los Angeles, twelve lanes of gridlock. I used to commute from Redondo Beach to Irvine and I had this rule: if I could get to Beach Blvd by 6AM I was free and clear. Well, over time, 100,000 other commuters had the same rule and eventually I would have to leave by 4:30AM to get to work on time. That was exactly what was happening with us. There was so much gridlock that we started inventing "sales alerts", phantom orders that "might" turn into real orders. If we could just start earlier, we might ship on time. It didn't work.

With this in mind, Bill repeated himself: "I'll help you solve delivery, but not on 80,000 SKUs. I can't defy the laws of physics. How about we start with a much smaller set and see if we can get to 80% of revenue?" John agreed. Bill's brilliance in this case was twofold: one, he scoped the project to a manageable size. All of the previous initiatives failed because we tried to boil the ocean. Second, his target was meaty enough that it would significantly move the needle on the overall problem. Luckily, to get to 80% of revenue required solving lead-times on about 2,000 SKUs. Not your typical 80/20!

A week later, David Choe (me), the director of strategy was wandering through the hallway. Bill called me into his office. "Young man, how would you like a real job in operations?" I quickly replied, "I would love it." Managing corporate strategic planning was fun, but as a former West Point infantry officer, I always longed to be where the action was thickest. Bill sat me down and explained the situation. I gulped and honestly, I saw the word "failure" flashing in front of me. To accomplish this project would literally require a business model transformation and we had just spent millions on failed initiatives. Now, my butt was in the hotseat.

I quickly assembled a cross-functional team and met with them on a cold wintry day in Minnesota last December. We decided to map out what it took to book and ship an order. In the history of our company, this had never been done. After four days and hundreds of post-it notes, we showed all the hands offs and steps on a 12ft x 8ft mural. It was so large, we couldn't tape it on the wall. The centerpiece of our process was what we dubbed "the circle of death."

The circle of death was the product of our build-to-forecast mess. Since customers couldn't get products on time, they started giving us request dates of "today" and even "Jan 1, 1900" in the hopes that their order would get bumped forward in the queue. With over 30,000 orders per month, this phenomenon turned into white noise. We only worked on orders where the salesperson and customers were yelling the loudest. Back and forth the emails and phone calls would go. The process was essentially a negotiation. The customer would ask for delivery today on products where we had no forecast visibility. Operations would immediately reply with a "90-day" lead time. Customer service would hit the "expedite" button. Operations would then reply with a "50-day" lead time. The sales person would yell and scream. Operations would then start looking at capacity, scheduling, and materials and then commit to a "45-day" lead time. This process would go back and forth for a week until ops gave their best and final: "40-days." This exhausting circle-of-death aggravated customers, infuriated sales people, and wore down everyone from customer service through supply-chain. But, we created a ship-to-promise metric that stated we were 97% on time to that final commit date!

As we stared at this mural we created, it was like we were staring into the abyss. Yes, we knew theoretically we would have to implement a pull-replenishment system instead of a build-to-forecast model, but to execute this seemed impossible.

West Point taught me that when the bullets are flying, the platoon leader needs to quickly take charge and clearly articulate next steps. Research has shown that soldiers will, in the thick of battle, follow the most clear and confident voice, even if that "follow me" is coming from a private. I decided that where all the other initiatives failed, boiling the ocean, we would succeed by scoping our first project for success. We decided we would pilot our future state process on just one product line and 36-part numbers. As small as this was, even this at the time seemed like a massive undertaking.

In order to ship these 36-part numbers on time (at a 95% service level, from a 65% current state), we would have to eliminate expediting, maintain a kanban of raw materials, and implement a lean manufacturing cell. While sales was quoting "7-21 days" on these 36 parts, our suppliers were quoting us "60-90 days". We would have to align the entire value-chain on a single lead-time. I asked the sales team, "if we get you to 14-days, will that be good enough? Instead of the circle of death, we will confirm 14-days to the customer in 24-hours. But once we do, you have to promise us not to expedite." Our sales team replied "if you can get to 14-days and commit in 24-hours, we will have a competitive advantage! By the way, we don't want to expedite. That takes up 40% of our time. We only do it because you guys give us ridiculous 90-day lead times."

With sales on board with the end-state, we created 3 teams to work on the underlying processes. One team would work on the order management process. A second team would work on supplier-alignment. And a third team would work on lean cell design. In order for us to implement pull replenishment, we needed dozens of people on the frontlines to work with us. But, we had to overcome years of cynicism and mistrust.

"Will this flavor of the month go away too?"

"I have tons of other things to do."

"What are we going to call this one?"

As part of the management "buzzwords," management talked about empowerment all the time. But over the years, employees learned that this meant nothing. Whenever they tried to act empowered they got their hands slapped. "How come I wasn't invited to this meeting?" Or, "you never cleared this with the steering committee." Or, "we need to get approvals before we do anything." Over time, people learned to just do what they were told and since there were enough crises-of-the-day, most people were content to keep their heads down.

I decided to try something different. We were going to execute and not continuously ask for permission. We would execute so fast and show results so quickly, that VP-types wouldn't have time to react. I got the idea from studying how fighter pilots dogfight. Although employees were tentative at first, we held several kaizen events where we empowered employees and made changes on the spot. We saw immediate results. In one lean-cell kaizen, we improved cycle time 60% in one week! People started to get more confident.

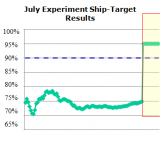

I put a line in the sand and said, "team, we need all of these workstreams to converge by March 1. We basically have 100-days to show management results." With the confidence they were gaining from the kaizens, the team went into overdrive. I briefed upper management and the sales organization on the "March Experiment." We would shut off expedites and only build to a real order. People were nervous on Feb 27th and then we went live.

Almost like magic our ship-to-target jumped from 65% to 97%. Our lead-times dropped from 50-days to 14-days. Although the pilot was small, we shipped about $1M of product, not too small that the results were insignificant.

The team was elated. Management was ecstatic. Sales was enthusiastic. But how do we keep the momentum going?

Editor's Note: This is Part One of a three-part story. Click here for Part Two and Part Three.

Cynicism and lack of engagement: We solved this through implementing change on the spot during kaizen events. We created momentum through results.

On-time delivery: from 65% to 97%

Randy - he took a massive risk and realigned all of his commodity managers around Pull

Shiv - our "sensei" master black belt

Fab - our "kaizen master"

Mario - aligned his whole factory around Pull

Kim, Melissa, Scott, Ricardo, Elias, Cheryl, Mary, Chuck, Randy, Tyler - our core team. They did all the work

Plus, hundreds of colleagues in Sales, Customer Service, Juarez operations, Shakopee operations, supply-chain, St. Teresa distribution, IT, product management who locked arms and pulled in the same direction

THANK YOU! You inspire me and inspire the world.

I'm inspired. I tried something similar but didn't have the nearly the support you were able to muster up. Next time...!!!!

- Log in to post comments

This is a great example of how solving big problems in small pieces can have drastic changes in all aspects of an organization’s business model, from sales and marketing to operations and upper management. The underlying assumption that organizations sometimes forget is that they serve their customer first and foremost. If the current system in use is not efficient and effective, the customer is the one that gets affected the most. The problems then arise internally when one group is pitted against the other.

This is very similar to the organization that I work for. The problem with our organization is that we do not deliver a product to our end customer, we deliver services and our customers provide information to us in return. The question that is a bit harder to solve for us is: how do we use “kaizen-events” to help our organization fix many of the similar problems faced. Due to unclear objectives, stagnation and, now, the built-up cynicism within the organization we end up working twice as hard for half the results. Our deliverables aren’t fulfilled in time and our customers get despondent and that flows into our workforce.

- Log in to post comments

- Log in to post comments

- Log in to post comments

Quite impressive turn around! It is the unfortunate reality that many manufacturing corporations who are in need of making such changes often find themselves struggling against internal red tape more so then external factors. Your story supports the importance of pulling from the outliers within an organization to gain a new perspective on the given situation. It is great when companies project an image that they empower their employees to make the crucial decision; however, it is small handfuls that are brave enough to do so! Innovation and change stems from those willing to take a risk. Even if the risk is unsuccessful, the demonstration to think outside the box will ultimately lead to further innovation! Congratulations on your success!

- Log in to post comments

- Log in to post comments

Dave, a truly impressive and inspiring story. Of course, your leadership success and indefatigable pursuit of excellence are no surprise to those of us who have known you a long time. I was especially impressed about your use of PGA style jackets to encourage and recognize excellence. So many managers fail to look beyond financial or trinket incentives. Very creative.

- Log in to post comments

Dave, a very good story that I greatly enjoyed reading here from Afganistan. I was completely captivated by the similarites to what I went through here getting my organization to adopt a model for continuous planning. There were quite a few of the same personality dynamics in place. I took the stance that there should never be any time as the Theater Engineers that we should not be planning; and that it was all a matter of innovation, the right model, and inclusion. Like you, I found myself being sometimes leader, sometimes coach and enabler, sometimes follower and sometimes swashbuckling pirate. I hope you are continuing to do well and I look forward to staying in touch with you.

- Log in to post comments

Inspirational story which speaks volumes about positive attitude, good planning, leadership and team work.

- Log in to post comments

Great to read this piece, David. I definitely think there is a book in it. Go for it!!!

- Log in to post comments

Its really a game changer. Excellent Story Dave!!!

- Log in to post comments

David,

This is an wonderful project and feels great to know that we are a part of it. your article has explained the process you followed in form of a story, that can be implemented, replicated and to draw inspiration from

great work!!

- Log in to post comments

- Log in to post comments

David,

Nice lesson on how to overcome cynisism, skeptisism and reslience with positive attitude, strong leadership and hard work. Well written too!

- Log in to post comments

David, you need to forget about making money and come join the public sector where your strategic thinking and operational problem-solving would affect generations - especially in the education realm where dinosaurs still roam. Come and reform the public school system and get our country back on track to compete with the rest of the world.

Continue to lead with integrity, courage, vision and passion.

With Courage We Soar!

- Log in to post comments

- Log in to post comments

Dave,

This is being a great job by yourself, and I meant writing this story and most important, being a leader of this initiative. People are really engaged on this trip and looking forward to continue the deployment of best practices.

- Log in to post comments

David. I'm strongly convinced that strategically this is a great project. We are enjoying the benefits of it.

Other intangible benefit that we are experimenting is the cultural change, due to continuous improvement. I believe in the power of Lean tools; I believe in Teamwork, and I believe in your leadership.

I don't know if this project will win, but I hope that this initiative could be spread around the Tyco Operations. " TIME AS A WEAPON "

- Log in to post comments

- Log in to post comments

Dave - I'm not surprised that you took on a radical revision of existing systems to get results! Getting buy-in along the way is so important, so your story is really amazing. Wish you lots of luck.

- Log in to post comments

Dave, excellent story indeed. Inspiring, and especially educative - I can learn a lot from this. As usual, seeing different perspectives and understanding people is key! GRAZIE! giu

- Log in to post comments

I has been a great experience working with this new project, we found a new way to make the supply chain more efficient and capable of meeting the client expectations.

I participate on the first wave of this pull/stimulus program and I can say that we have been developing new methods and processes since then, the people of all departments is completly aware and commit about this program.

- Log in to post comments

- Log in to post comments

Dave It is a great proyect, I'm very happy because I participe in this proyect

Best Regards

- Log in to post comments

Dave It is a great proyect, I'm very happy because I participe in this proyect

Best Regards

- Log in to post comments

great story. well-written, compelling, with a plot and character development. you humanized the experience and frustrations felt within a company, showing how personalities and management styles are often in conflict when dealing with overcoming obstacles.

i was engaged in the experience, waiting to see how it would end up and inspired by possibilities and change, when all odds are stacked against you. it felt very much like a rooting for the underdog story.

- Log in to post comments

- Log in to post comments

Dave, you have done a great job in steering an entire organization in the same direction and towards the same goal. I am really proud to be part of the group of people that got fired up with such an innovative approach. It is great to see so much excitement and a sense of accomplishment all across ADC now Tyco Electronics. You are a true leader!!!

- Log in to post comments

As one of the production planners who is currently participating in this transition, I am very excited to see that many of the improvements I only dared to dream of, are becoming a reality. I am very proud to be part of the awesome team involved with this innovative movement and I look forward to this transformation positioning us even more positively in this industry. Thank you David for starting the movement!

- Log in to post comments

I am proud to be one of the ADC now Tyco Electronics team because it has been awesome to see how our customer service has been improved since we started to develop this strategy,

- Log in to post comments

I am currently participating in this business transformation and I am very excited and happy to be part of it

- Log in to post comments

It is good to know that we have a Great coordinator who has given us the opportunity to work as a whole team with all plants participants and who has the compromise and commitment and continue to follow up on the results and who has encourage everyone to see what we have from a different perspective (see everything out of the box) so improvements can be made to a current goal

- Log in to post comments

David,

You have done an outstanding job of transformation and of describing the transformation. Keep up the good work.

Dewayne

- Log in to post comments

David,

As a complete outsider to this business arena you were able to write in such detail that I could understand what you were trying to convey in your overall message. Your inspiring story of innovation, and goal setting is inightful. I found your simplistic approach to problems "how do I do this" very meaningful. The article was well written, and enjoyable. Great job!

Jon Kautz

- Log in to post comments

- Log in to post comments

dave, as you usual you are so inspiring and have such an innovative approach in all that you do... especially in the area of leadership. you are a truly gifted communicator. thanks so much!!!!

- Log in to post comments

This strategy is definitely inspiring and transferable. Thanks for sharing David!

- Log in to post comments

David has truly inspired the troops in the Mexican Operation Plants and started the movement. We all knew we needed to reeach out across the silos of our value chain , but it was him, bringing the rigth players in the righ sequence applying lean techniques that made the difference. Our perfomance in service indicators are the best in decades thanks to the movement he initiated

- Log in to post comments

- Log in to post comments

This is Game Changing Leadership! When is the book coming out?

- Log in to post comments

- Log in to post comments

When is the book coming out? I want to know more!

- Log in to post comments

David Choe has lead the way in innovation from the field as a platoon leader to the board room.

- Log in to post comments

Excellent story about positive change. I especially like the approach of breaking the delivery problem in to smaller sets of skus to make the task achievable and manageable. Good work!

- Log in to post comments

- Log in to post comments

Great story David, with impressive results. Don Limacher

- Log in to post comments

How to start a movement in your company by David Choe.... I saw him work is magic in a room full of vollenteers he is truely amazing and a positive change agent. Lori Olson

- Log in to post comments

Thanks for sharing this inspiring story Dave, I applaud your keen efforts for change. You also make a good case for a community such as the MIX where folks can come to gain support when efforts appear to be on a steep incline. It's been my experience that others who join your efforts will also strengthen them, and so you are headed in terrific directions by your collaborative efforts. Even as we renew broken practices - we can create a deeper problem when we step back into old assumptions or stop developing an awareness of the real impact of new directions. Look forward to hearing your next advances!

- Log in to post comments

- Log in to post comments

Dave, as you look back on this, does it appear obvious that this was the solution? Isn't it amazing how we humans are like that? There is the slow creep of more and more assumptions becoming tacit over time - because it becomes accepted (we've always done it this way) and because people who knew have moved on. Cross functional teams and sitting down and mapping out processes & work have such power.

I can only suggest 'a' way to keep momentum going that I've used and seen work:

1. reward the team in various, creative, meaningful ways - which means not always money but time, recognition, fun

2. find other challenges like this one (I’m sure there are more) and engage some of the same people and perhaps others more related to the challenge to grow the base of success and enthusiasm

3. one of my clients has a ‘challenge of the month’ that starts teams working together.

Usually, there is no shortage of challenges – a key is continued recognition, reward, and making the results tangible (e.g., comments from customers, financial metrics of improvement, etc.). Hope this helps! Anxious to read Part II!

deb

- Log in to post comments

- Log in to post comments

Dave, what an amazing story, thanks for sharing it on the MIX. Look forward to reading Part 2!

Michele

- Log in to post comments

You need to register in order to submit a comment.